Cnc Coolant To Water Ratio

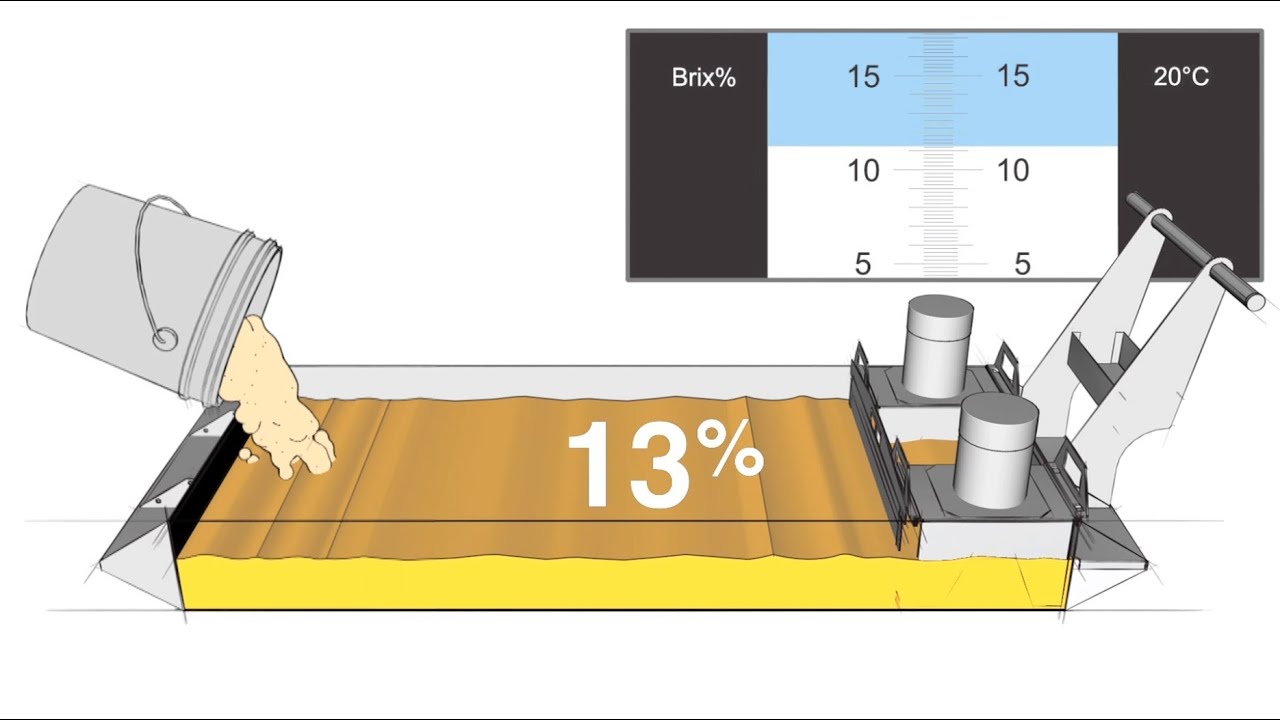

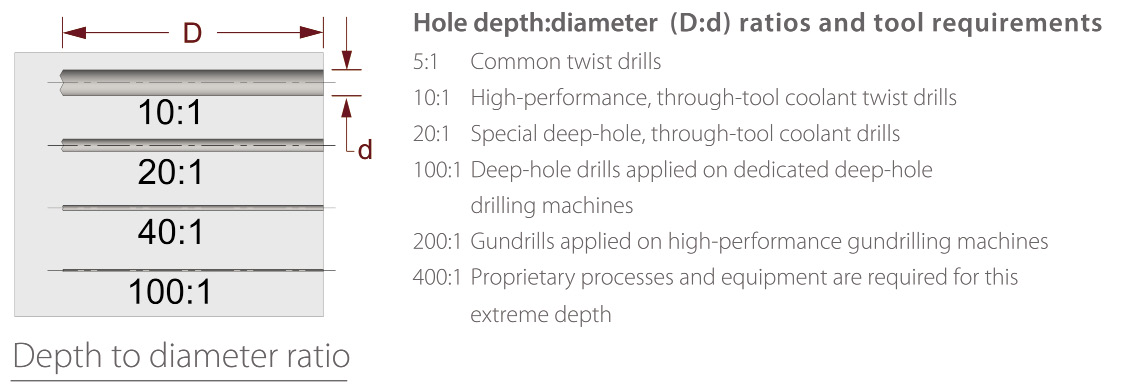

For example if your percentage is 4 take 100 4 which is 96 so your mix ratio is 96 4 which can then be reduced to.

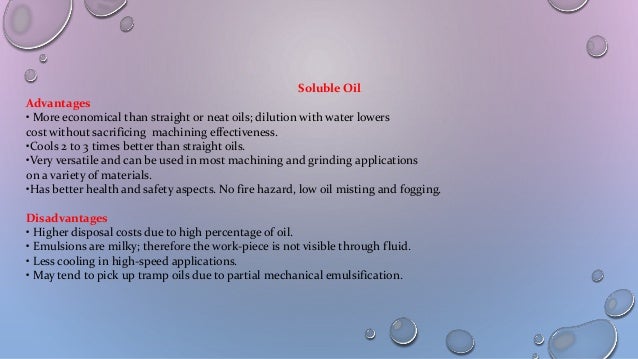

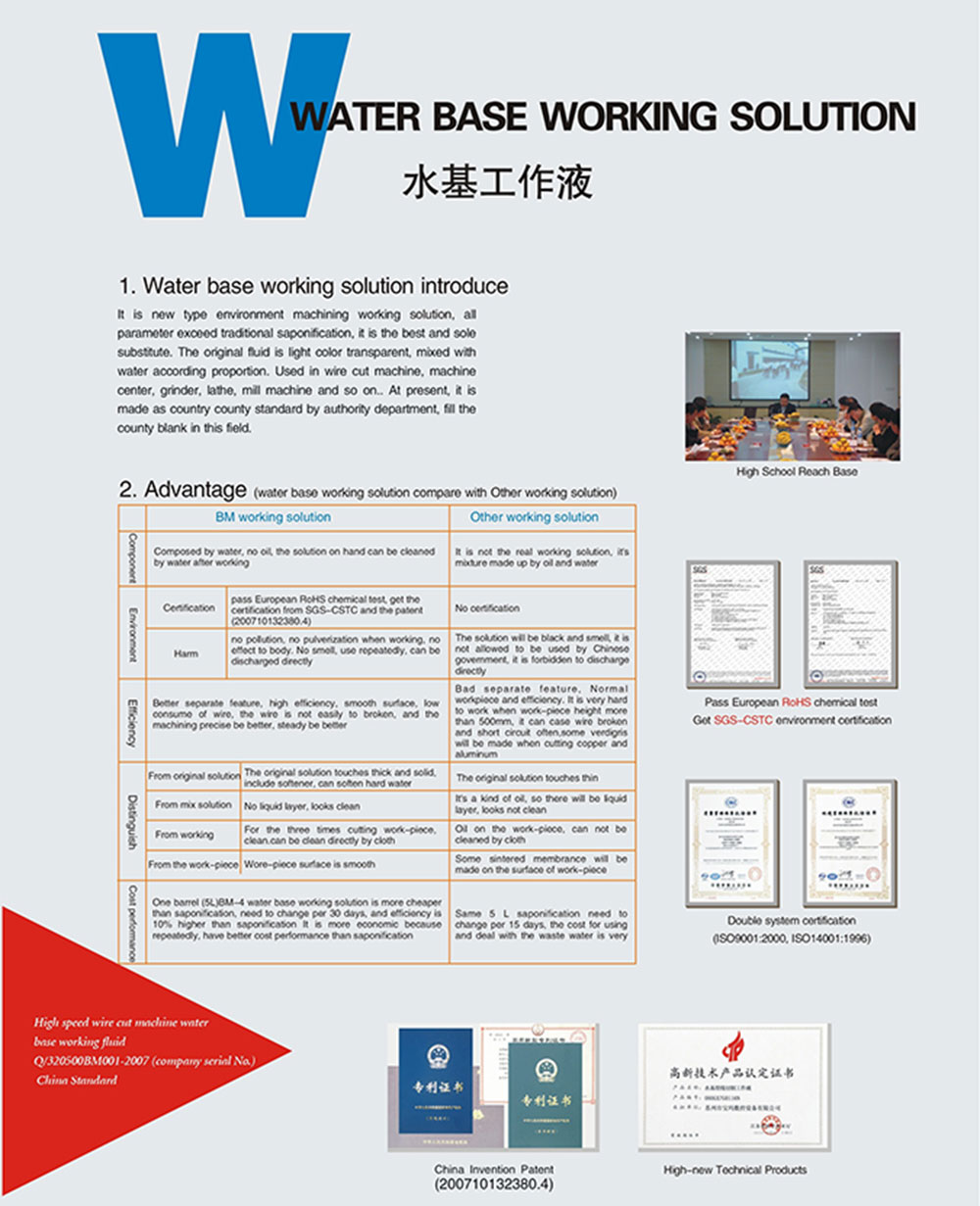

Cnc coolant to water ratio. Properly maintaining the coolant concentration level can not only extend the service life of the coolant but also extend the service life of tools and machines. Be sure to maintain your coolant. There are various kinds of cutting fluids which include oils oil water emulsions pastes gels aerosols mists and air or other gases cutting fluid are made from petroleum distillates animal fats plant oils water and air or other raw ingredients. We tried hoses that we could just run into the.

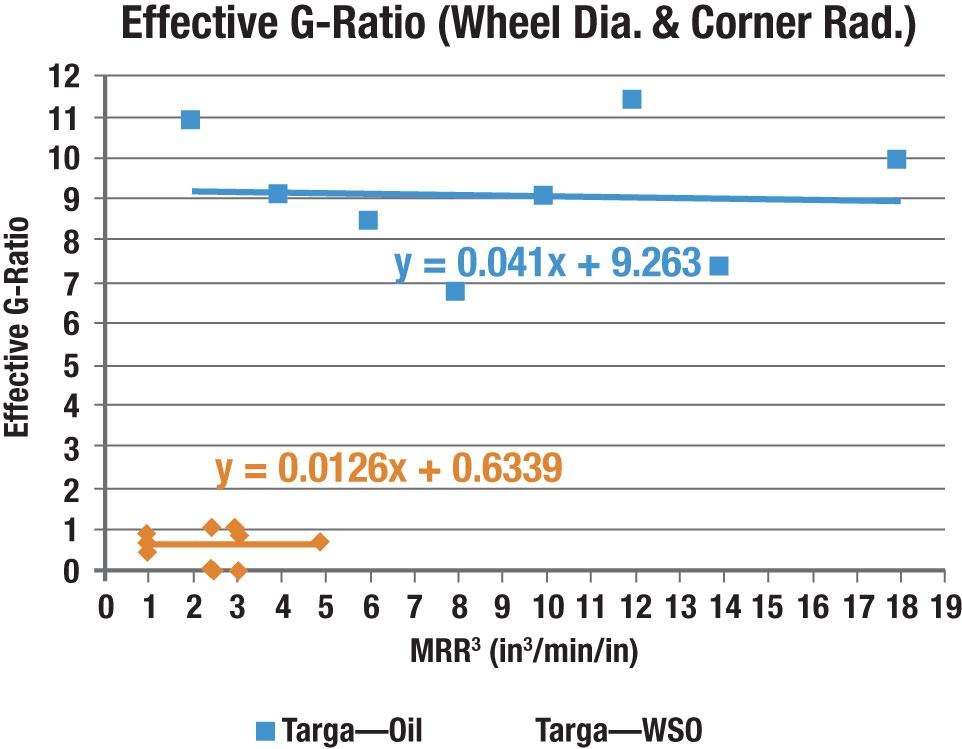

If your mix ratio is 4 1 or 4 parts water to 1 part solution there are 4 1 or 5 parts. For instance the manufacturer of a 3 axis cnc milling machine will provide detailed data on not only the type of coolant required but also the concentration level of the coolant. What i ve seen is mix the coolant and keep it in an ibc tote 275 gallons. Greencut plasma is a water soluble package blends with water at 20 1 ratio easily rinsable with water.

As the level drops you make up the difference with a 100 1 mixture. If you are new to mixing and maintaining coolant we recommend that you start with tools of coolant. In addition to requiring the correct ratio of water to antifreeze the coolant has to cycle through the coolant system in order to properly cool the engine. It is specific to the coolant.

So maybe 6 places in the shop you can turn on a valve and get mixed coolant or water. Cutting fluid is a type of coolant and lubricant designed specifically for metalworking processes such as machining and stamping. The mixing percentage is 20 1 divided by 5. Buckets are still required but it s a short walk.

In most places including your local gas station you can buy pre mixed coolant which is usually 50 50 anti freeze and water. If the manufacturer says 10 1 then you use that originally. The basic principle behind antifreeze is that it lowers the freezing point and raises the boiling point of the water within the radiator. This video gives you a complete overview of the tools you will need to make your coolant maintenance easier.

Make up mixture should be the original mixture diluted 10 to 1. However when mixed with water at a 50 50 ratio it can withstand temperatures as cold as 35 f before freezing. Coolant is an important part of cnc machining process they help to extend the life of the tool and improve the surface finish of the processed parts. Does not leave marks no sump clean outs needed for at least one year with proper maintenance and pump circulation.

How to calculate mix ratio if percentage is known 100 the percentage. Then we used a diaphragm pump to pump the mixed coolant overhead to the machines.